In contrast to classic process validation, which frequently depends on predefined checks and evaluations conducted at particular points in time, CPV entails continuous process monitoring making use of Innovative analytical technologies and methodologies.

During the continued process verification phase, different process effectiveness indicators are monitored in order that the process is functioning in just appropriate boundaries. These indicators could incorporate yield, cycle time, process ability indices, and also other relevant metrics.

In addition, it emphasizes the value of threat assessment, the place potential dangers associated with the process are discovered and mitigated.

It helps manage product or service safety and efficacy, minimizes defects, and guarantees compliance with marketplace regulations, eventually protecting customer security and manufacturer popularity.

When picking concurrent validation, gathering facts to prove that each merchandise batch is dependable and fulfills all of the necessary criteria is essential.

Customise an extensive GMP validation instruction system in accordance with the demands of your respective Firm.

The science and threat-based technique combines merchandise improvement know-how having a structured process performance and solution excellent monitoring system to provide for validation through the entire product or service lifecycle.

Process Improvements: Modifications from the manufacturing process, such as mixing times and drying temperatures.

The second phase includes demonstrating the process is able to persistently manufacturing items that fulfill the predetermined high website quality attributes. It contains the execution of validation protocols to validate the process effectiveness and the collection of data to help the validation.

Process validation provides a large number of Advantages that could drastically greatly enhance your online business operations and solution outcomes. Here’s the way it may make a variance:

Process validation is usually labeled into four types dependant on the phase in which the process is getting evaluated:

Standardize strategies: Producing and adhering to standardized strategies guarantees consistency across all validation actions. process validation in pharmaceuticals By generating detailed protocols, you lower variability and be sure that each crew member follows the identical methods.

Scale your frontline functions with customizable software program that boosts good quality, basic safety, operations and compliance. Sign up for cost-free

In conclusion, process validation is a crucial component of top quality assurance within the manufacturing market. It makes sure that manufacturing processes are capable of regularly producing superior-high-quality items that meet shopper necessities and regulatory expectations.

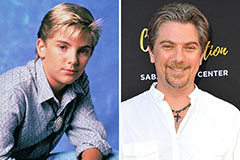

Jake Lloyd Then & Now!

Jake Lloyd Then & Now! Jeremy Miller Then & Now!

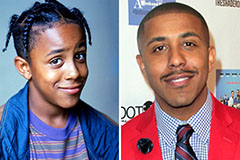

Jeremy Miller Then & Now! Marques Houston Then & Now!

Marques Houston Then & Now! Tyra Banks Then & Now!

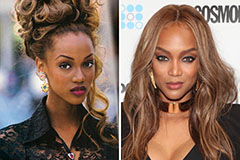

Tyra Banks Then & Now! Justine Bateman Then & Now!

Justine Bateman Then & Now!